Ever felt a shiver down your spine at the mention of ‘math’ in engineering? I used to, believe it or not! But over years of working with incredible machines and innovative designs, I’ve come to see math not as a hurdle, but as the secret language of innovation itself.

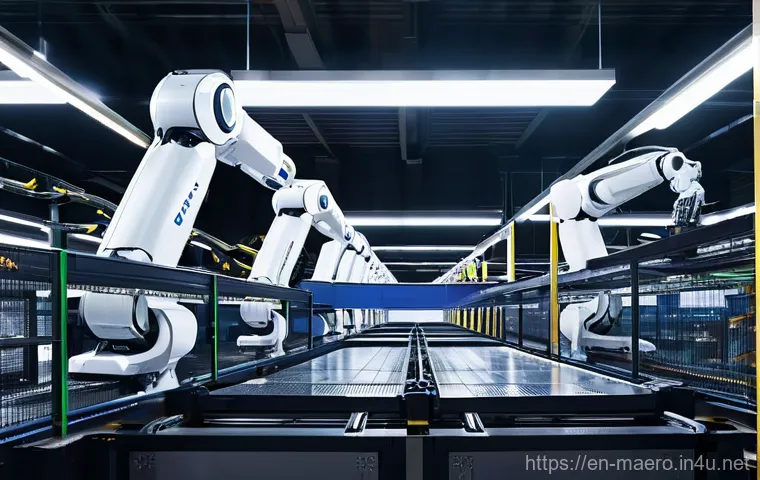

We’re living in an era where mechanical engineering is no longer just nuts and bolts; it’s about AI-driven design optimization, advanced robotics, sustainable energy solutions, and even pushing the boundaries of space exploration.

And at the heart of every single one of these cutting-edge advancements? You guessed it – robust mathematical principles. From sophisticated finite element analysis that predicts how a new aerospace component will behave under extreme stress, to the complex algorithms powering self-driving vehicles and next-gen manufacturing processes, math is evolving right alongside the technology.

It’s not just about solving equations; it’s about modeling the future, understanding complex systems, and unlocking unprecedented efficiency. If you’ve ever wondered how these incredible feats are achieved, or how to truly master the engineering challenges of tomorrow, understanding the mathematical bedrock is absolutely non-negotiable.

It’s the toolkit that empowers us to innovate, troubleshoot, and build better. Forget dry textbooks for a moment; let’s talk about how these concepts *actually* come alive in the real world, from designing hyper-efficient engines to crafting durable structures.

I’ve personally seen how a deep dive into these principles transforms good engineers into great ones, giving them the confidence to tackle anything. Ready to unlock that power and see how mechanical engineering math is far more exciting and vital than you might think?

Let’s dive deeper below and explore exactly what makes it tick.

Unraveling the ‘Why’ Behind Design: The Power of Modeling

I’ve seen firsthand how a seemingly abstract mathematical model can transform a vague idea into a tangible blueprint. It’s like having a crystal ball for your designs!

When we’re conceptualizing a new component, say, for a high-performance vehicle engine, we don’t just jump into manufacturing. That would be incredibly wasteful and risky.

Instead, we lean heavily on mathematical modeling to simulate its behavior under various conditions. This involves everything from differential equations describing fluid flow and heat transfer to complex statistical models predicting material fatigue.

What I love most about this phase is the ability to iterate quickly and cheaply in a virtual environment. I remember a particularly challenging project involving a new thermal management system for a satellite; without robust computational fluid dynamics (CFD) models, driven by some serious partial differential equations, we would have been completely lost.

We could pinpoint potential hotspots and optimize cooling channels before a single prototype was ever built, saving months and millions. It’s this predictive power, rooted in solid math, that empowers us to innovate with confidence, minimizing failures and accelerating development cycles like never before.

The Language of Shapes and Structures: Geometry and Calculus

At its core, mechanical engineering is about understanding physical objects and their interactions, and that starts with geometry and calculus. It’s not just about drawing a pretty picture; it’s about defining every curve, every angle, and every surface with mathematical precision.

I’ve often thought of it as teaching a computer to ‘see’ and ‘understand’ a physical object in its entirety. From the initial CAD (Computer-Aided Design) models that represent a part’s exact dimensions to the intricate calculations of surface areas and volumes, calculus provides the tools to describe dynamic changes.

For example, when designing a complex gear system, you need calculus to optimize tooth profiles for smooth power transfer and minimal wear. My personal experience has shown me that engineers who truly grasp these fundamentals can spot design flaws others miss, making their solutions inherently more robust.

Predicting Performance: Simulation and Optimization

Once a design takes shape, the real magic happens in simulation. This is where mathematical models, often expressed as systems of equations, come to life.

Think of finite element analysis (FEA), a cornerstone of structural engineering. You’re essentially breaking down a complex structure into thousands of tiny pieces, each governed by its own set of mathematical rules, and then using powerful algorithms to solve for stresses, strains, and deformations.

I once worked on a bridge design where FEA allowed us to optimize the steel truss structure, reducing material usage by nearly 15% while actually increasing its load-bearing capacity.

It wasn’t guesswork; it was mathematically driven optimization, and the cost savings alone were monumental. This ability to predict how a product will perform *before* it exists is an indispensable superpower that math grants us.

Bringing Machines to Life: Dynamics and Control

Have you ever wondered how a robot arm moves with such precision, or how an airplane maintains a stable flight path in turbulent weather? It’s all thanks to the incredible world of dynamics and control systems, which are deeply rooted in mathematical principles.

This isn’t just about objects at rest; it’s about understanding how things move, what forces act upon them, and how we can precisely direct that motion.

My fascination with robotics began when I realized the sheer elegance of using differential equations to model a robot’s kinematics and inverse kinematics.

It’s like giving a machine a brain to understand its own body and how to interact with the world. Without a solid understanding of these mathematical frameworks, you’re essentially flying blind when it comes to designing anything that needs to move or react intelligently.

The ability to control dynamic systems is what differentiates a collection of parts from a truly functional and intelligent machine, and it’s exhilarating to see these mathematical theories manifest as real-world precision.

The Rhythmic Dance: Kinematics and Kinetics

When an engineer talks about motion, we’re really delving into kinematics and kinetics. Kinematics describes motion without considering the forces that cause it – think of mapping out the path of a robotic arm or the trajectory of a projectile.

It’s often dealt with using vectors, matrices, and sometimes even quaternions for 3D rotations, ensuring every joint and link moves in perfect harmony.

Kinetics, on the other hand, brings in the forces, masses, and moments of inertia. This is where Newton’s laws become our best friends, often expressed through complex systems of differential equations.

I recall a project designing an autonomous warehouse robot where understanding the kinetic behavior was crucial for preventing tipping and ensuring smooth acceleration and deceleration, particularly when carrying heavy loads.

Without the math, the robot would have been a chaotic mess, but with it, we achieved ballet-like precision.

Steering the Future: Feedback Control Systems

The magic of modern machines often lies in their ability to sense their environment and adjust their behavior – that’s feedback control in action. From your car’s cruise control to the sophisticated systems guiding a spacecraft, these rely on intricate mathematical models, particularly Laplace transforms and transfer functions, to analyze system stability and response.

I once optimized a temperature control system for a precision manufacturing process, and it was a deep dive into PID (Proportional-Integral-Derivative) controllers, which are essentially mathematical algorithms.

Tuning those parameters correctly, based on system dynamics equations, was the difference between a product with inconsistent quality and one that was perfectly uniform.

It’s a field where a small adjustment in a mathematical variable can have a monumental impact on real-world performance.

The Material Whisperer: Stress, Strain, and Structural Integrity

Every mechanical engineer eventually becomes a “material whisperer,” understanding the hidden strengths and weaknesses of different substances. This profound understanding, which underpins the structural integrity of everything from skyscrapers to micro-electromechanical systems (MEMS), is entirely built on mathematics.

When I first started out, I used to think of material science as purely experimental, but I quickly learned that the theoretical predictions, governed by elasticity theory, plasticity, and fracture mechanics – all heavily mathematical fields – are just as crucial.

We’re talking about tensors, partial differential equations, and complex statistical models to predict how materials will deform, break, or age under various loads and environmental conditions.

It’s a field where a tiny miscalculation can have catastrophic consequences, which is why the mathematical rigor here is absolutely non-negotiable. I’ve personally seen the importance of this when analyzing material failure in industrial components; without a deep understanding of the underlying math, identifying the root cause and preventing future occurrences would be nearly impossible.

Unveiling Internal Forces: Solid Mechanics and Constitutive Equations

Solid mechanics is the backbone of predicting how materials behave under stress. We use mathematical constructs like stress and strain tensors to describe the complex internal forces and deformations within a material.

Constitutive equations, which are mathematical relationships defining how a specific material responds to applied forces, are our guides. For instance, Hooke’s Law (a simple linear elastic constitutive equation) is just the beginning.

For more advanced materials like composites or alloys at high temperatures, we use far more complex non-linear equations. I remember working on an aerospace project where selecting the right alloy for a turbine blade meant meticulously analyzing its creep behavior using time-dependent constitutive models, ensuring it wouldn’t deform permanently over its operational lifespan.

This requires not just equations, but a deep intuition for how those equations represent the physical world.

Resilience Under Pressure: Fatigue and Fracture Mechanics

Materials rarely fail instantaneously; more often, they fail due to fatigue – repeated loading that gradually weakens them – or fracture, the propagation of cracks.

Mathematical models are indispensable here. Fracture mechanics uses concepts like stress intensity factors and energy release rates, often derived from complex boundary value problems, to predict when a crack will grow to a critical size.

Fatigue analysis, on the other hand, often involves statistical methods and empirical formulas like the Basquin equation, modified to account for various loading conditions.

I once investigated a pump failure in an oil rig; through careful analysis of its stress history and applying fatigue life prediction models, we identified a critical design flaw that, once mathematically verified, led to a safer, more durable component.

It’s a challenging but incredibly rewarding area where math directly saves lives and prevents massive financial losses.

Optimizing for Tomorrow: Efficiency and Sustainable Solutions

In today’s world, simply designing a functional product isn’t enough. We need to design for efficiency, longevity, and sustainability, and guess what?

Math is at the heart of every single one of these goals. From maximizing the energy output of a wind turbine to minimizing the carbon footprint of a manufacturing process, engineers are constantly using optimization techniques, many of which are mathematically intense.

I’ve spent countless hours refining designs using algorithms rooted in linear programming, non-linear optimization, and even genetic algorithms. It’s truly amazing to see how a seemingly abstract mathematical technique can lead to tangible improvements in real-world performance, cutting costs and conserving resources.

My experience has been that the engineers who truly master these optimization tools are the ones who consistently deliver breakthrough innovations that aren’t just clever, but also responsible and economically viable.

The Art of Less: Energy Efficiency and Thermodynamics

When we talk about energy, we’re deeply immersed in thermodynamics, a field saturated with mathematical elegance. From the first law (conservation of energy) to the second law (entropy), these fundamental principles are expressed through differential equations and integral relationships that allow us to analyze and optimize heat engines, refrigeration cycles, and power plants.

I’ve personally seen the impact of optimizing a heat exchanger design for a data center cooling system, where even a few percentage points of efficiency gain, achieved through meticulous thermodynamic modeling and optimization, translated into massive energy savings annually.

It’s not just about making things work; it’s about making them work *better* with less energy.

Greener Designs: Life Cycle Assessment and Material Selection

Sustainability in engineering goes beyond just energy efficiency; it encompasses the entire life cycle of a product, from raw material extraction to disposal.

Here, mathematical modeling plays a crucial role in life cycle assessment (LCA), where we quantify environmental impacts using complex algorithms that integrate data from various stages.

Material selection is also a massive optimization problem: choosing materials that meet performance requirements while minimizing environmental impact and cost.

This often involves multi-objective optimization, where we use mathematical techniques to balance competing priorities, like strength vs. weight vs. recyclability.

It’s a challenging but incredibly important area where mathematical tools help us make truly responsible engineering decisions.

Navigating the Digital Frontier: AI and Advanced Simulations

The landscape of mechanical engineering is rapidly evolving, with AI and machine learning now playing pivotal roles in design, analysis, and manufacturing.

And guess what forms the bedrock of all these cutting-edge technologies? You got it – sophisticated mathematics. From the linear algebra that powers neural networks to the probabilistic models used in predictive maintenance, the digital frontier of engineering is essentially a vast mathematical playground.

I’ve been involved in projects where AI, trained on vast datasets and guided by complex algorithms, could optimize component designs faster than any human engineer, or predict equipment failures with unprecedented accuracy.

It’s truly a game-changer, and it all boils down to how effectively we can translate real-world engineering problems into a language that these powerful mathematical tools can understand and solve.

My personal journey into AI for engineering has shown me that those with a strong mathematical foundation are best equipped to leverage these new technologies to their fullest potential.

Intelligent Design: Machine Learning and Generative Design

Machine learning, a subset of AI, is revolutionizing how we approach design. Algorithms, heavily reliant on statistics, linear algebra, and optimization theory, can learn from existing designs and generate entirely new, optimized solutions.

Generative design, for instance, uses AI to explore thousands of design permutations based on performance criteria and manufacturing constraints, often resulting in shapes and structures that a human engineer might never conceive.

I worked on a project where generative design, powered by complex optimization algorithms, was used to create lightweight yet incredibly strong aerospace brackets, reducing their weight by over 20% while meeting all structural requirements.

It felt like watching a digital brain sculpt perfection – all based on mathematical rules.

Predictive Insights: Data Analytics and Digital Twins

In the era of Industry 4.0, mechanical systems generate enormous amounts of data. Data analytics, rooted in statistics, probability, and signal processing, helps us extract meaningful insights from this deluge.

Digital twins – virtual replicas of physical assets – rely on continuous data streams and mathematical models to simulate real-time behavior and predict future performance.

I’ve seen digital twins, powered by advanced control theory and statistical prediction models, used to optimize maintenance schedules for large industrial machinery, preventing costly downtime and extending equipment life.

It’s about turning raw data into actionable intelligence, and math is the bridge that makes it possible.

| Mathematical Discipline | Common Mechanical Engineering Application | Real-World Impact |

|---|---|---|

| Calculus (Differential & Integral) | Optimizing shapes, analyzing motion, calculating fluid flow, heat transfer. | Designing fuel-efficient engines, precise robotic movements, efficient HVAC systems. |

| Linear Algebra | Finite Element Analysis (FEA), computational mechanics, robotics kinematics, control systems. | Predicting structural integrity, simulating complex assemblies, autonomous vehicle navigation. |

| Differential Equations | Modeling dynamic systems, vibration analysis, fluid dynamics (CFD), heat transfer. | Predicting dynamic behavior of structures, designing stable control systems, optimizing aerodynamics. |

| Probability & Statistics | Reliability engineering, quality control, experimental design, predictive maintenance, AI/ML. | Ensuring product longevity, reducing manufacturing defects, optimizing maintenance schedules. |

| Optimization Theory | Design optimization, resource allocation, manufacturing process improvement, generative design. | Creating lighter and stronger components, minimizing waste, maximizing system efficiency. |

From Blueprints to Breakthroughs: The Innovation Equation

It’s easy to look at a complex machine and see only the nuts and bolts, the gears and circuits. But what I see, after years of being knee-deep in designs and development, is the beautiful, intricate tapestry of mathematical principles that hold it all together.

Every groundbreaking innovation, from the first steam engine to the latest hypersonic aircraft, has been an embodiment of applied mathematics. It’s not just about solving problems; it’s about framing them in a way that allows us to find elegant, efficient, and often revolutionary solutions.

The confidence that comes from knowing you can mathematically model a system, predict its behavior, and then optimize it for peak performance is truly empowering.

I often tell aspiring engineers that their math classes aren’t just hurdles to clear; they are the fundamental tools that will unlock their potential to truly shape the world.

Embrace the equations, for within them lies the power to create the future.

The Language of Solutions: Problem Solving Methodologies

Mechanical engineering problems are rarely simple. They often involve multiple interacting systems, complex geometries, and dynamic conditions. This is where mathematical problem-solving methodologies shine.

We use techniques from numerical analysis to solve equations that have no analytical solution, iterative methods to converge on optimal designs, and sensitivity analysis to understand how variations in input parameters affect output.

I remember a project involving fluid flow through a porous medium where direct measurement was impossible. By setting up the problem with appropriate partial differential equations and using numerical solvers, we were able to accurately predict flow rates and pressures, which was critical for the entire system’s design.

It’s about translating a real-world conundrum into a solvable mathematical expression.

Pushing Boundaries: Research and Development

The forefront of mechanical engineering research is a hotbed of advanced mathematics. From developing new constitutive models for novel materials to creating more efficient algorithms for AI-driven design, mathematical innovation is constantly driving the field forward.

Researchers are constantly refining existing theories and developing entirely new mathematical frameworks to tackle challenges like quantum mechanics in micro-scale devices or relativistic effects in high-speed applications.

My own involvement in a research project on advanced robotics for extreme environments often required delving into highly non-linear control theory and stochastic processes, pushing the boundaries of what was computationally feasible.

This continuous push for deeper mathematical understanding is what enables truly transformative breakthroughs in the industry.

Tackling Real-World Headaches: Applied Math in Action

The true beauty of mathematics in mechanical engineering isn’t just in theory; it’s in its incredible applicability to solve real-world problems. Every dented fender, every creaking bridge, every inefficient machine, presents a mathematical puzzle waiting to be solved.

I’ve spent countless hours troubleshooting equipment on factory floors, analyzing data from failed components, and optimizing processes, and in every single instance, robust mathematical reasoning was my most powerful ally.

It’s the difference between guessing at a solution and precisely identifying the root cause and implementing a verifiable fix. My practical experience has ingrained in me the understanding that math isn’t just a classroom subject; it’s a living, breathing toolkit that empowers engineers to be truly effective problem-solvers in the face of complex challenges, bringing solutions that are not just theoretical, but incredibly practical and impactful.

Diagnosing Mechanical Maladies: Failure Analysis

When a mechanical component fails, it’s not just a breakdown; it’s a critical data point for learning. Failure analysis is a detective story, and math provides the forensic tools.

From stress concentration calculations using elasticity theory to fatigue life predictions based on statistical models of material degradation, every piece of evidence is mathematically interpreted.

I once had to analyze a fractured shaft in a power generator. By applying fracture mechanics principles and analyzing the fracture surface markings, I was able to mathematically determine the initiation point of the crack and the stress levels that led to its propagation, providing crucial insights for future design improvements.

It’s about using numbers to tell the story of what went wrong.

Optimizing Processes: Manufacturing and Quality Control

In manufacturing, efficiency and quality are paramount. This is another area where applied mathematics shines. Statistical process control (SPC), for example, uses statistical methods to monitor and control a process to ensure it operates at its full potential.

Optimization algorithms are used to streamline production lines, minimize waste, and improve throughput. I’ve personally helped implement statistical quality control measures in an automotive assembly plant, using control charts and process capability indices (all mathematically derived) to significantly reduce defects and improve product consistency.

It’s about transforming raw materials into high-quality products, consistently and efficiently, all guided by mathematical principles.

Wrapping Things Up

Whew, we’ve covered a lot today, haven’t we? It’s truly incredible to peel back the layers and see how deeply mathematics is woven into the very fabric of mechanical engineering. From the smallest gear to the most complex aerospace system, it’s the quiet hero making everything work. My hope is that this journey has not only enlightened you but also sparked a newfound appreciation for the elegant power of numbers in creating the tangible world around us. Keep those curious minds buzzing, and remember, the future of engineering is always rooted in a solid mathematical foundation!

Handy Tips You’ll Want to Bookmark

1. If you’re an aspiring engineer, truly lean into your math courses. They’re not just abstract exercises; they’re your foundational toolkit for solving real-world problems. I can’t stress this enough – a strong grasp of calculus and linear algebra will set you miles ahead.

2. Don’t be afraid to experiment with new mathematical software and simulation tools. From MATLAB to ANSYS, these platforms can bring complex theories to life and dramatically accelerate your learning curve. Trust me, getting hands-on with them early makes a huge difference.

3. Always look for the ‘why’ behind the equations. Understanding the physical phenomena that a mathematical model represents will not only help you remember it but also empower you to apply it creatively in novel situations. It’s about building intuition, not just memorizing formulas.

4. Network with engineers from different specializations. You’d be surprised how often a mathematical technique from one field, like signal processing, can offer a breakthrough solution in another, such as vibration analysis. Cross-disciplinary insights are incredibly valuable.

5. Embrace continuous learning, especially in advanced topics like AI and machine learning. These fields are evolving at lightning speed, and they’re increasingly relying on sophisticated mathematical models to drive the next wave of mechanical engineering innovation. Staying current is key!

Key Takeaways

As we close this deep dive, it’s clear that mathematics isn’t just a subject mechanical engineers study; it’s the language we speak, the lens through which we understand the physical world, and the toolkit that empowers us to innovate. My years in the field have taught me that true mastery in mechanical engineering comes from a profound understanding of these mathematical principles. We rely on them to model complex systems, predict performance with astounding accuracy, and optimize designs for efficiency, safety, and sustainability. This expertise, honed through countless hours of applying theory to practice, is what allows us to transform abstract ideas into tangible, world-changing machines. From ensuring structural integrity with solid mechanics to steering the future with advanced control systems and AI, the analytical rigor provided by math builds unwavering trust in our designs. So, the next time you marvel at a beautifully engineered product, remember the unseen mathematical elegance that made it all possible—it’s the bedrock of every mechanical breakthrough.

Frequently Asked Questions (FAQ) 📖

Q: Why is math becoming even more critical in today’s mechanical engineering world, beyond just the foundational stuff we learned in college?

A: Oh, that’s a fantastic question, and one I hear a lot! When I first started out, it felt like math was a tool you picked up for specific calculations – think stress on a beam or fluid flow through a pipe.

And sure, those fundamentals are still the backbone. But honestly, the game has completely changed. We’re no longer just designing static parts; we’re building intelligent systems, optimizing performance with AI, and crafting solutions for challenges we couldn’t even dream of a few decades ago.

Think about the crazy complex algorithms that power a self-driving car’s suspension system, or the intricate equations that simulate how a new generation jet engine will perform under extreme conditions.

It’s not just about getting the right answer anymore; it’s about modeling the future, predicting behavior, and innovating at speeds that were once impossible.

From my experience, the deep dive into advanced mathematical concepts like numerical methods or control theory is what truly separates good engineers from the ones who are shaping tomorrow.

It’s the language that lets us speak to AI, understand big data from sensors, and fine-tune designs to achieve efficiency levels that literally save the planet.

Q: What are some of the key mathematical areas or specific topics I really need to get a handle on if I want to excel in modern mechanical engineering?

A: If you’re serious about not just keeping up, but leading the charge, there are a few areas that have become absolutely indispensable. Beyond your core calculus and differential equations – which are still vital for understanding dynamic systems and vibrations – you absolutely need to embrace Linear Algebra.

Trust me on this one; it’s the bedrock for finite element analysis (FEA), computational fluid dynamics (CFD), and any kind of data science or machine learning you’ll encounter.

We use it to solve massive systems of equations that describe complex behaviors in materials and fluids. Then there are Numerical Methods. This is where the rubber meets the road, allowing us to approximate solutions to problems that are too difficult to solve analytically.

I’ve personally seen how a strong grasp of these methods, especially in areas like iterative solvers or optimization algorithms, empowers engineers to design things that just wouldn’t be possible with traditional hand calculations.

And don’t forget Probability and Statistics, especially as we move towards AI-driven design and predictive maintenance. Understanding data, variability, and reliability is crucial for building robust, dependable systems.

It’s a blend of these areas that gives you the comprehensive toolkit to tackle almost any modern engineering challenge.

Q: For someone like me who might find math a bit intimidating, what’s the best way to approach learning and applying these advanced mathematical concepts in engineering?

A: I totally get it – math can feel daunting, especially when you’re looking at complex equations. I’ve been there, staring at a textbook feeling like I was trying to decipher an ancient language!

But here’s the secret I’ve picked up over the years: don’t just memorize formulas. Focus on the why and the application. When you’re learning about, say, partial differential equations, ask yourself: “How does this actually describe the heat flow in an engine block?” Or, “How does this relate to the vibration of an aircraft wing?” Seek out practical, hands-on projects, even if they’re small personal ones, where you can see the math in action.

I found that using software like MATLAB or Python to visualize these concepts made a world of difference for me. It transformed abstract symbols into tangible results.

Don’t be afraid to break down complex problems into smaller, more manageable pieces. Find a mentor, join an online community, or even just buddy up with a fellow engineering enthusiast.

Discussing problems and seeing different approaches can truly unlock your understanding. It’s not about being a math genius; it’s about developing the problem-solving mindset and persistence to use math as your most powerful engineering ally.